Fellow Portrait

Erin Keaney

Nonspec

Affordable and adjustable prosthetic limb kits for amputees

North America

UNITED STATES

Fellow

2018

Updated March 2018

Like father, like daughter

As a little girl, Erin Keaney looked with amazement at the medical devices her father, a plastics engineer, would bring home from work. Two decades later, it was the turn of her audience at a university presentation to be amazed at an adjustable prosthetic arm and mechanical hand Erin and her team had crafted for just 75 USD as part of an undergraduate competition. Erin brought her experience from her Plastics Engineering degree to make the design possible for pennies on the dollar. After the presentation, a member from the audience challenged her team to see if this was something they could carry forward to help people in developing countries.

Erin learned that three million amputations are carried out every year, with a high rate of below-the-knee amputations in India specifically. While prosthetic limbs are already available, the high cost of their fabrication and fitting (about 20,000 USD) means that only a relatively small number of people can afford them. The situation becomes more complicated with children, who would need several different-sized prosthetic limbs until they reach adulthood.

Whilst considering her future, it was the Boston Marathon bombings in 2013, where sixteen people suffered from loss of limbs that was the turning point for Erin. “I followed the amputees’ journeys in the media and I was shocked to learn that so many couldn't afford devices to get moving again. It showed me that a lack of affordable devices wasn’t just a problem in developing countries like India, but is also an issue at home in my own backyard.”

After the Boston Marathon bombing it just really hit home that this is something that can make a difference all over the world.

Making prosthetic limbs affordable and adjustable

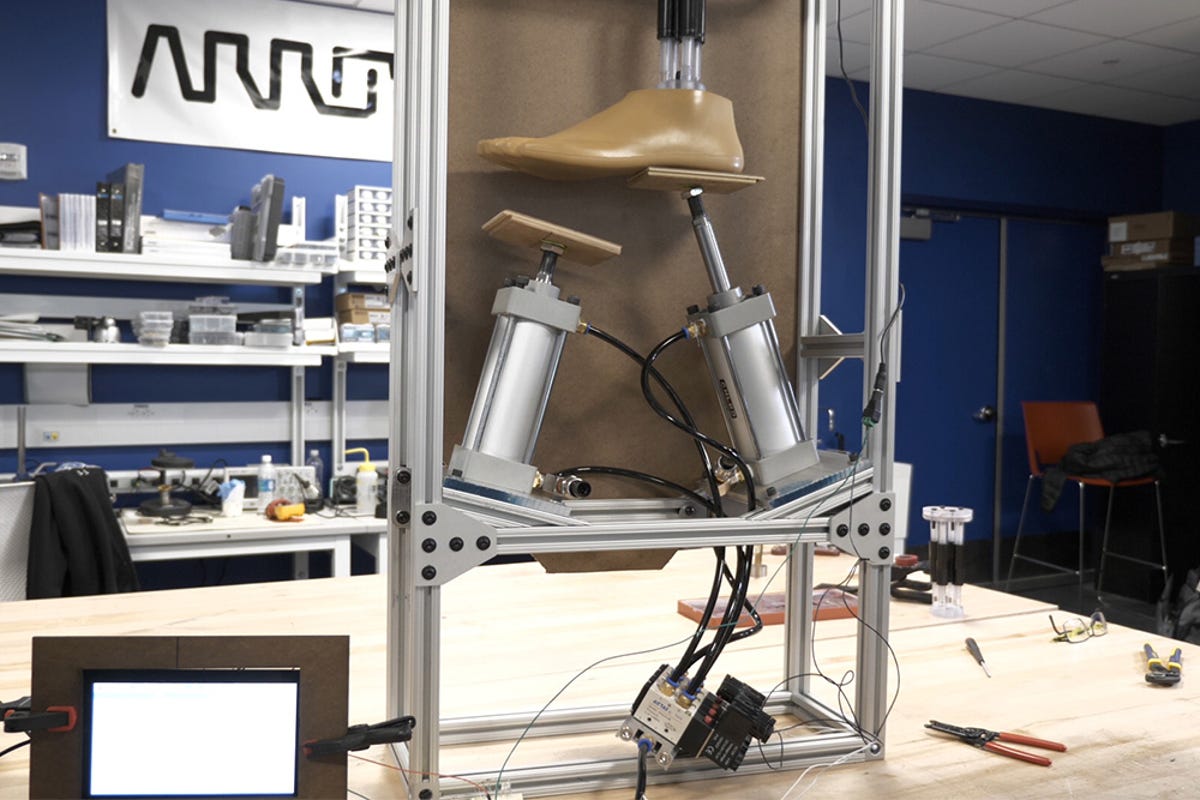

With a determination to make a difference, Erin founded Nonspec in the USA to produce adjustable prosthetic-limb kits for clinics to easily fit amputees, without the need for specialised equipment, tools or training, at an affordable price.

Erin’s devices are unique thanks to their hyper-adjustability with the device able to adapt to a range of patient sizes. The mass production of parts that form the devices have allowed for a price point of 150 USD, which is considerably cheaper than the market average. Whilst the Indian market is the primary focus during the initial start-up phase, Erin intends to expand her offering to the US market and worldwide as her business grows.

At present, there are six people fitted with Nonspec prosthetic limbs, and Erin has been able to closely follow the changes that her product has made to their lives. “Seeing the difference that my product can make in people’s lives is what keeps me motivated and focused. The second patient to be fitted with one of our devices is now able to play with her daughter, bend her knees and return to her previous job as a nurse having left because of her previous ill-fitting prosthetic.”

We’re trying to solve the problem that 54 million amputees have: most of them don’t have access to a device that works in their day to day life. We’re trying to change this by providing a kit that can be adjusted to any patient who comes in the door, in under an hour.

Innovation is the key to success

Nonspec already secured an order of 750 units, and while expanding the sales of her products is a priority for Erin, she sees her primary goal as furthering research and innovation of affordable medical devices. Continuously improving her product has been Erin’s key to success: “It is important to listen to everyone’s advice, and search for patterns in the constructive feedback.”

She has encountered many obstacles on her way, but through her compassion has remained undaunted: “From having to pivot from arm prosthetics to legs, to being ignored for my age, and told that my products cannot be done for the price I was quoting, I have faced challenges at every turn. I have gotten through them by thinking about how much I can improve someone’s life.”

Seeing the difference that my product can make in people’s lives is what keeps me motivated and focused.