Fellow Portrait

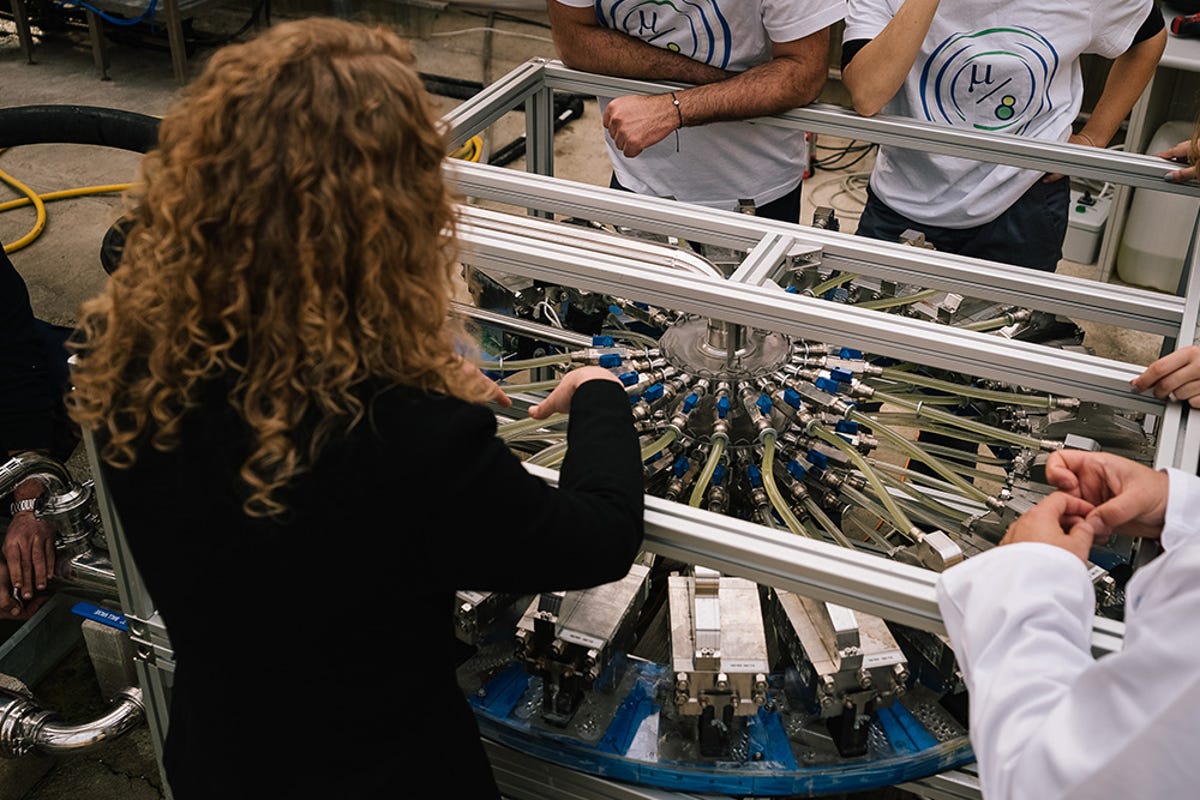

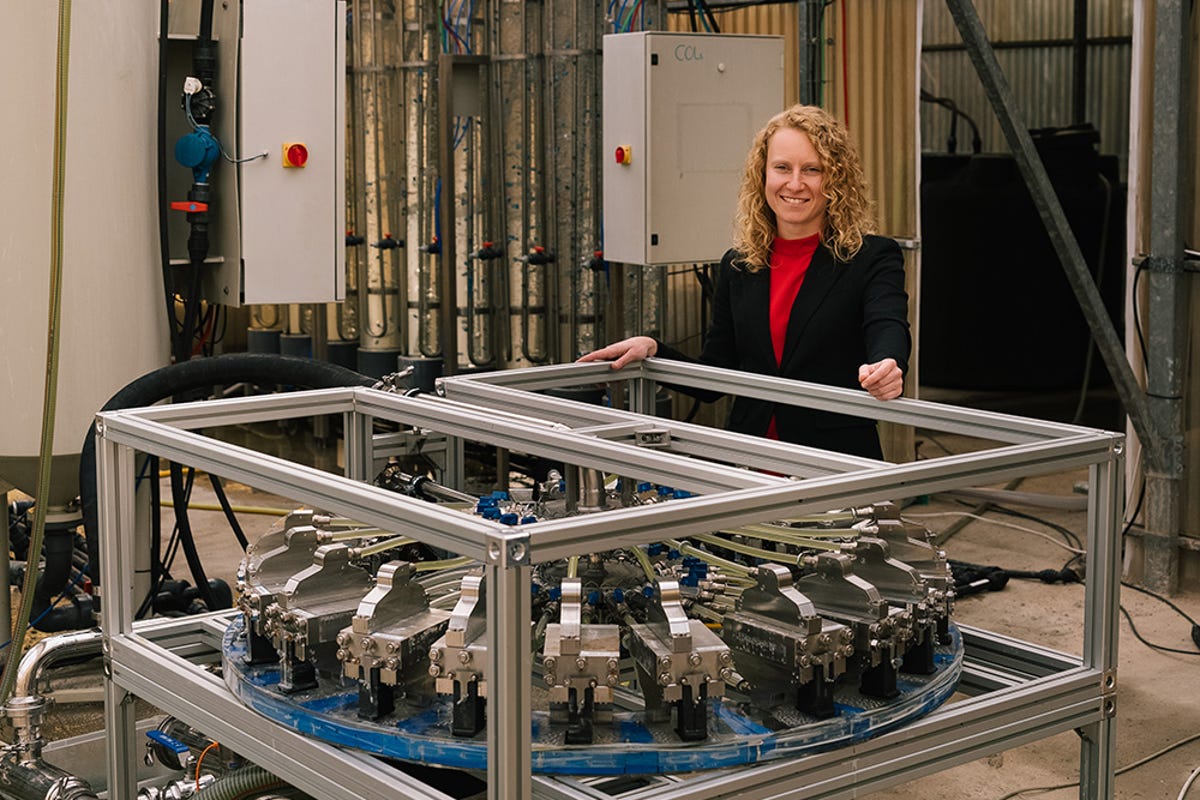

Monika Tomecka

uFraction8

uFraction8 develops filtration systems that help manufacturers of products like lab-grown meat harvest and process more sustainably and efficiently.

Science & Technology Pioneer Award

Poland and Scotland

Fellow

2024

Updated March 2024

New food production methods are needed to feed the world’s growing population

In the face of increasing rates of hunger, scientists are looking for better alternatives to conventional meat sources. Globally, livestock production causes 18 percent of greenhouse gas emissions and takes up 30 percent of productive land. It is also a primary cause of deforestation.

“Conventional agriculture is damaging our planet,” says uFraction8 CEO Monika Tomecka. “We need more sustainable and more ethical ways to produce food for our world's growing population.”

Cultivated (or lab-grown) meat is one solution for addressing global food shortages. Its production uses 96 percent less water, emits 87 percent fewer greenhouse gases, and uses 90 percent less land than livestock production. Unfortunately, the cost of producing cultivated meat is almost ten times as high as animal protein, making it economically unfeasible.

“Most companies in the cultivated meat space are still working at a small scale, using batch production processes to make only enough meat to demonstrate safety to regulators,” Monika explains.

I know that at the rate the world’s population is growing, we don’t have enough food to feed everybody. The fact that I can play a role in finding solutions is amazing.

Microfluidics-based filter systems help bio-manufacturers produce larger quantities more efficiently

Monika was finishing a PhD in biomedical science when a business accelerator program paired her with an engineer developing a new water filtration technology. At first it seemed they had little in common, but they soon realized their project had applications beyond biology. When the accelerator program invested in them, they launched uFraction8.

“We decided that this technology could have a lot of potential to help bio-manufacturers, and that's how we started working together,” she says.

uFraction8 develops microfluidics-based filter systems that can help bio-manufacturers—such as lab-grown meat producers—harvest and process products more efficiently and at larger quantities, while using only one-quarter the energy of existing technologies.

“Our filtration technology enables continuous production, which can increase yield four to ten times,” Monika says.

Originally, Monika gave herself six months to see if uFraction8 would succeed. If it didn’t, she planned to return to her fiancé and research in Singapore. But the company began winning award after award, and Monika and her partners wanted to keep moving forward. “In the end, my relationship didn’t work out, but uFraction8 did,” she says.

Our technology helps bio-manufacturers obtain six to ten times more product from their existing bioreactors.

New technology seeks to enable large-scale production of cultivated meat

After successfully testing its technology with yeast and microalgae cultures, uFraction8 is now collaborating on tests with several bio-manufacturers.

“Every customer trial is its own win for us,” Monika says. “The fact that customers want to come back and try our technology on a bigger scale gives us a lot of joy as well, because it shows us there’s a need for it.”

Monika hopes that uFraction8’s technology will help increase global food security, increase access to medicines and nutrients, and preserve ocean life. “Our mission is to make sustainable manufacturing with biology affordable. Our technology could help enable the industrialization of cultivated meat. We like to say that we’re enabling the bio-economy of the future.”

If we can enable alternative ways of producing proteins, we can not only help feed growing populations with healthy food but also offset the negative effects of current methods of food production.